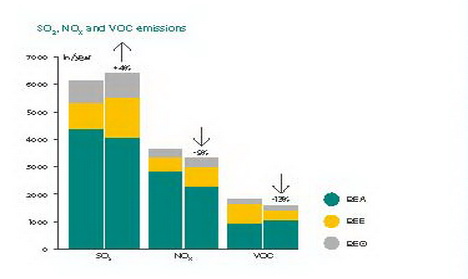

HELLENIC PETROLEUM aim at reducing both air emissions and waste generated, through specific actions; such as maximizing the use of gaseous and high environmental standards fuels and the implementation of advanced technologies in the production process. In 2015, at the three Group’s refineries, the main air emissions for the oil sector either decreased significantly (Nitrogen Oxides - NOx and volatile organic compounds - VOC reduced up to 13%) or remained at the same low levels (emissions of sulfur dioxide - SO2) in previous years. These are presented in detail in the Figure below. It is noted that the slight increase (4%) of SO2 emissions compared to the previous year, is due to a minor increase in consumption of liquid fuels in Elefsina refinery as a result of the scheduled shut down of Flexigas production unit (Flexigas is an environmentally friendly and zero-sulfur fuel gas).

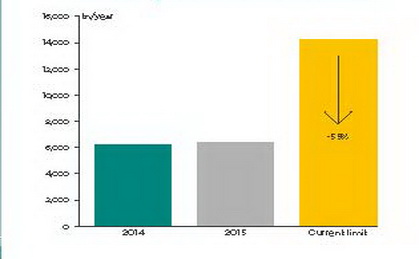

Regarding the compliance with the applicable legislative limits, indicatively, SO2 emissions remained much lower (-55%) than the current limit imposed by the environmental permit (in tn/year). It is underlined that the above mentioned limit on sulfur compounds emissions decreased in 2013 by 30% compared to the limit in force until 2012.

2014-2015 SO2 emissions compared to current limit

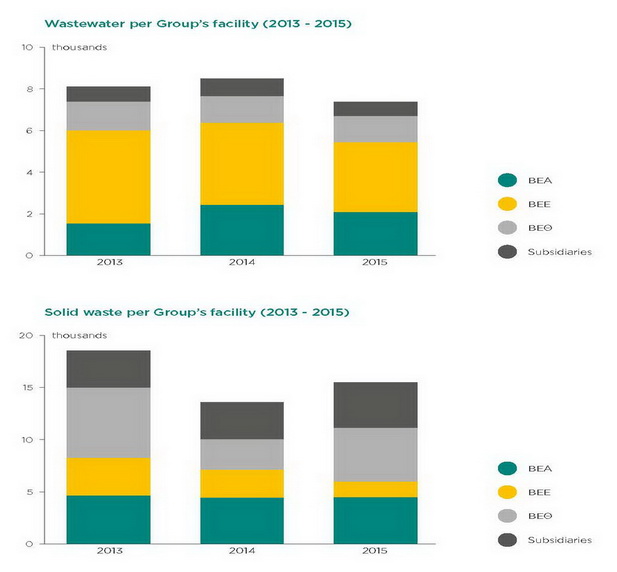

Regarding wastewater and solid waste management, primary objectives are the reduction of their output, by maximizing recycling for those waste streams that it is possible and for the rest of them, in situ management and treatment in the best possible way for the environment and human health.

HELLENIC PETROLEUM have invested in modern waste treatment facilities, such as the 3-stages liquid waste treatment units and the oily sludge treatment unit, using biodegradation technique, in Thessaloniki industrial complex. The latter, in 2014, managed to triple its efficiency and to improve the quality characteristics of final product for disposal by addition of specific bio-enhancing microorganisms in the process.

The Figures above present the comparison of the amounts of wastewater and solid waste, respectively. Noticeable is the reduction of liquid waste by 13%, which is directly related to the efficiency of the production and the waste management process. On the other hand, solid wastes, mainly linked to the efficiency and availability of solid waste processing units (either inside or outside the facility) showed an increase compared to the previous year, but remained at low levels compared with these past years.

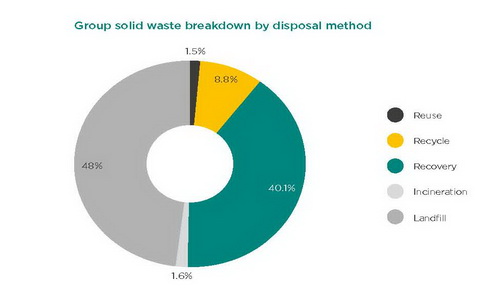

Figure above shows, in detail, the methods of disposal of solid waste; with over 50% of total waste recycled, recovered through raw materials recovery processes and reused.

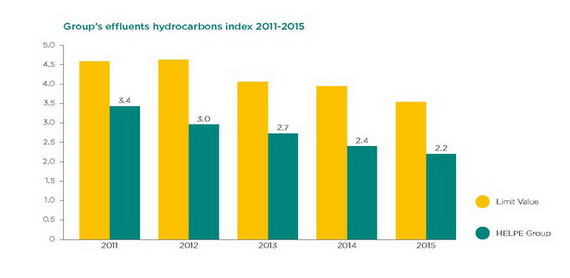

Moreover, improved performance in terms of quality of treated effluents continues and the reduction trend (35%) over the last 5 years for the three Group’s refineries is presented in the Figure below.